In digital textile printing, every fabric behaves differently and that’s where choosing the right machine makes all the difference. The right Hopetech printer ensures perfect ink flow, color precision, and production consistency, no matter what fabric you’re printing on.

Whether you work with cotton, polyester, viscose, silk, or blends, your machine’s printhead, ink system, fabric feed, and dryer setup must align seamlessly with your materials and workflow.

At TRUE COLORS, we help textile manufacturers identify which Hopetech model suits their specific fabric line — for maximum productivity and flawless print results.

What Makes a Hopetech Machine Right for Your Fabric Line?

A perfect machine match is defined by how well it fits your fabric, ink, and production requirements.

Here’s what to look for:

1. Fabric Compatibility

Each fabric type reacts differently to ink chemistry and heat.

- Natural fibres (Cotton, Linen): Best paired with machines supporting Reactive or Pigment inks for soft, breathable finishes.

- Polyester & Synthetics: Work beautifully with Disperse or Sublimation inks for vibrant, long-lasting prints.

Hopetech machines are engineered to handle both natural and synthetic materials efficiently — giving you the flexibility to expand your fabric line without switching systems.

2. Ink System & Printing Technology

Your ink defines your output and your machine must match it.

Hopetech printers from True Colors support Reactive, Pigment, Disperse, and Sublimation inks, ensuring every design gets the color depth and durability it deserves.

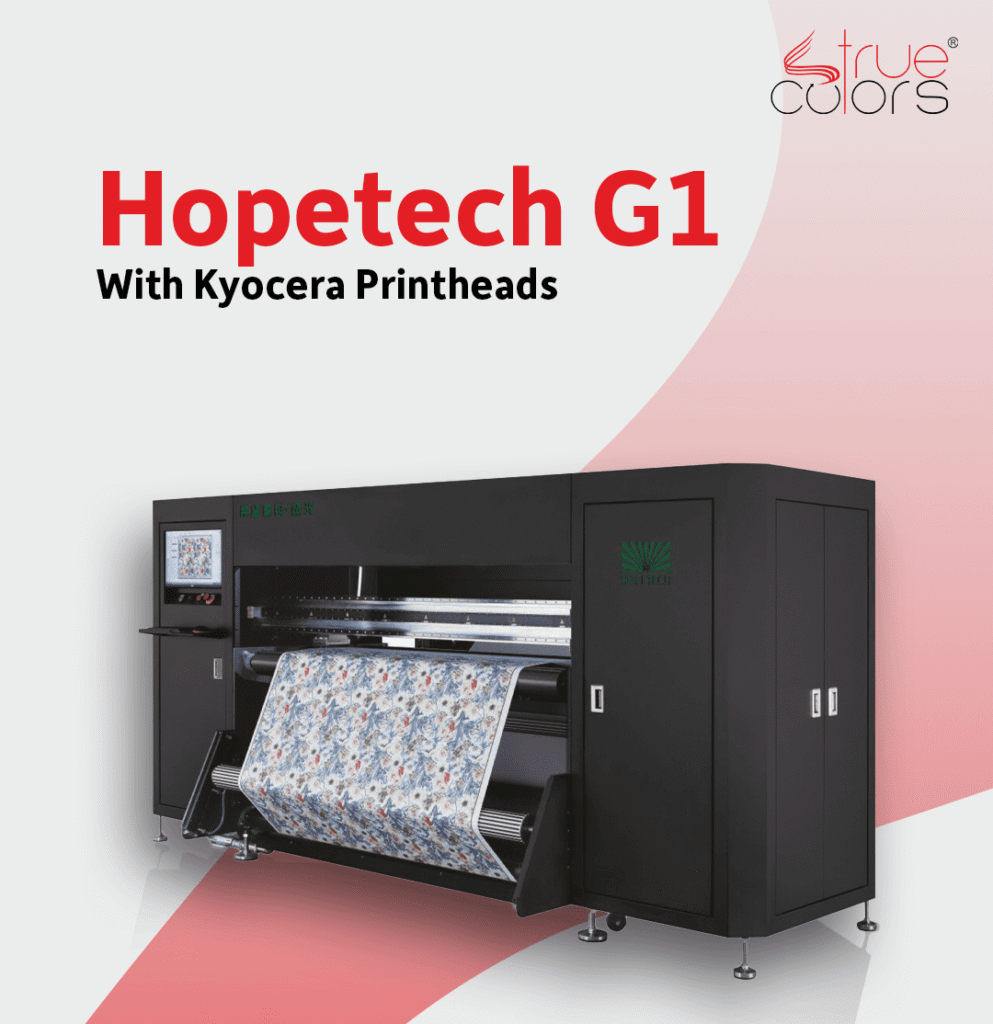

The Hopetech Q1, for example, offers:

- Multi-ink compatibility

- Stable color accuracy across production runs

- Uniform droplet control for clean edges and smooth gradients

This allows businesses to print everything from luxury cottons to fashion-forward synthetics with equal perfection.

3. Fabric Handling & Drying Precision

In high-speed production, fabric movement and drying uniformity are key.

Hopetech’s advanced glue belt conveyor and controlled fabric feeding system maintain perfect alignment, while its integrated drying units ensure fast curing without shrinkage or fading. This precise engineering minimizes waste and guarantees every meter looks as good as the designer imagined.

4. Service, Support & Ecosystem

Even the best machine needs strong support. TRUE COLORS backs every Hopetech installation with:

- India’s largest after-sales network

- Local spare parts & service availability

- Test print facility to help you validate quality before purchase

- Integrated ecosystem of ink, sublimation paper, and accessories — all designed to work perfectly together

When machine, ink, paper, and service come under one roof, efficiency soars and downtime drops.

Why Printers Trust TRUE COLORS for Hopetech Solutions

At TRUE COLORS, every installation is handled with precision and care. We don’t just sell machines — we help you build a long-term, reliable printing ecosystem.

Our experts assess:

- Your fabric type and blends

- Your production scale and target throughout

- Your preferred ink chemistry

- Your future scalability goals

Then we recommend the Hopetech model that aligns perfectly — ensuring better ROI, consistent color, and trouble-free operations.

Conclusion

For textile manufacturers, choose the right Hopetech machine isn’t just a technical decision — it’s a strategic investment in quality, speed, and growth.

With TRUE COLORS as your trusted partner, you get more than a machine — you get precision, service, and long-term reliability designed for the evolving needs of India’s textile industry.

Experience the difference with a TRUE COLORS Test Print — and find out which Hopetech machine fits your fabric line perfectly and choose the right Hopetech machine.