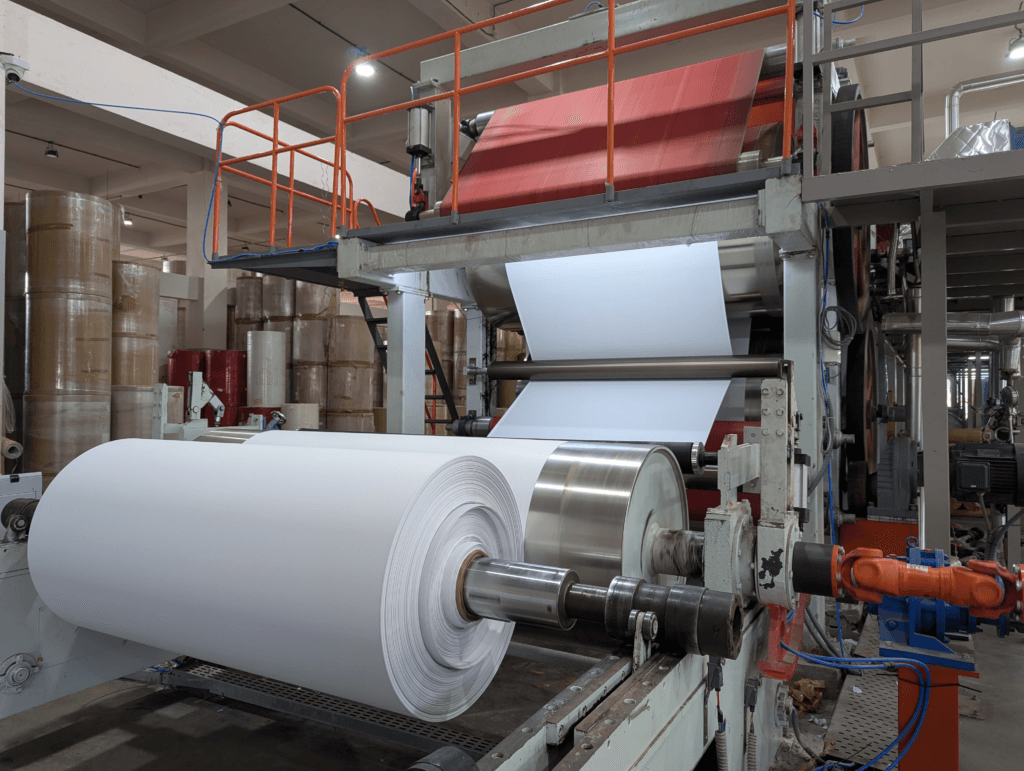

The Role of Coating in Sublimation Paper

In sublimation printing, the paper’s coating is the unsung hero. TRUE COLORS’ Quick-Dry Coating Sublimation Papers control how quickly ink dries, how cleanly ink releases to fabric, and how well colors remain crisp during transfer. A well-engineered quick-dry coating prevents prints from smudging or bleeding—especially at high speeds. Without it, even the best machines and inks can produce blurry edges or unwanted color blending.

What Makes a Good Quick-Dry Coating?

A high-performance quick-dry coating should deliver:

- Rapid Dry-to-Touch — The paper sets ink fast to minimize smudging during handling.

- Strong Ink Retention — The coating locks ink in place until heat triggers its release, preventing lateral spread or bleed.

- Clean Release During Transfer — The coating transfers nearly all the ink to fabric at transfer temperature, leaving minimal residue.

- Dimensional & Surface Stability — The coating resists curling, warping, cracking, or degradation under heat and humidity.

- Batch Uniformity — Every roll or sheet behaves consistently, reducing the need to tweak print settings.

If any of these fail, you will notice bleeding (ink spreading sideways), smudging (ink dragging), or faded edges.you’ll see bleeding (ink spreading sideways), smudging (ink dragging), or faded edges.

How TRUE COLORS’ Quick-Dry Coating Sublimation Papers Prevent Bleed & Smudge

TRUE COLORS engineers their sublimation papers for high-speed, clean transfers with claims like “dry faster, transfer cleaner.” Their coating technology works as follows:

- Fast Drying Formula — The coating dries ink quickly after printing, reducing smudging during handling.

- Optimized Ink-Holding Matrix — The coating keeps the dye in place until heat triggers release, preventing lateral bleed or blurring.

- Seamless Release on Heat — During transfer, the coating encourages almost complete ink transfer to fabric, reducing ghosting or residue.

- Stability Under Heat & Handling — The paper resists curling or deformation during printing and transfer, maintaining alignment and consistency.

- Designed for Their Ecosystem — TRUE COLORS fine-tunes the coating for optimal performance with their machines, inks, and fabrics.

Thanks to this coating, printers using TRUE COLORS papers experience fewer misprints, less waste, and crisper edges—especially at high speeds.

Conclusion

A strong quick-dry coating holds the key to clean, sharp, and bleed-free prints. TRUE COLORS’ advanced coating technology helps prevent bleeding, smudging, and ghosting—even at high speeds. Tuned for their ecosystem of machines, inks, and fabrics, these sublimation papers deliver predictable, high-quality results. Upgrading to coated papers like TRUE COLORS ensures high-speed, high-fidelity printing with minimal errors.