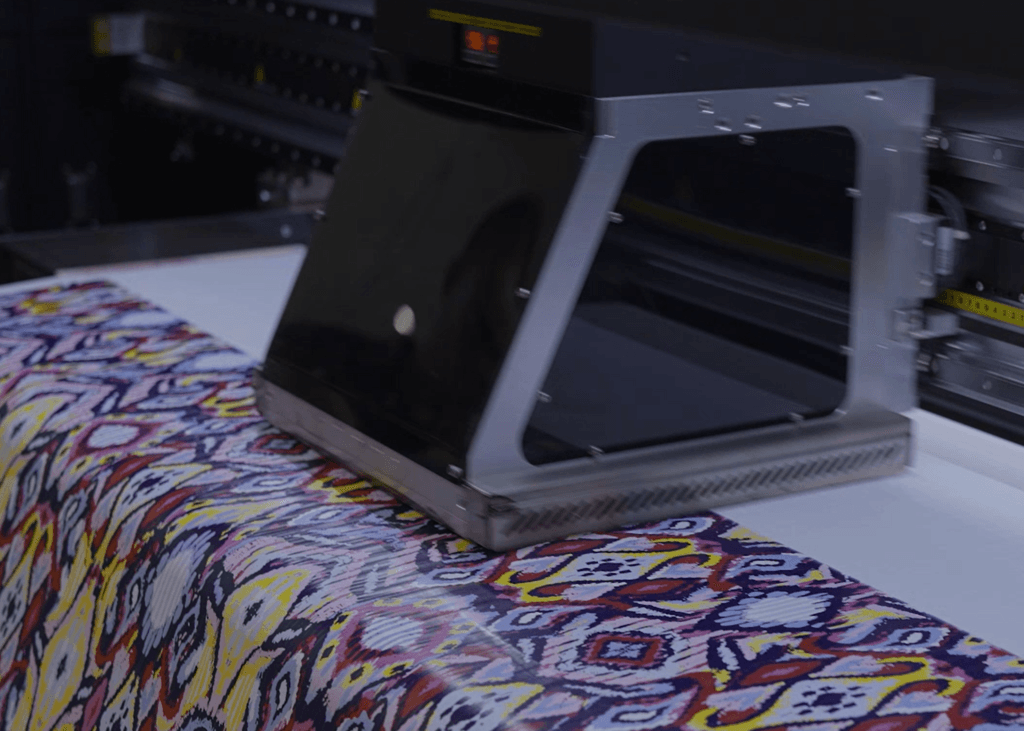

The Role of Ink in Digital Textile Printing

In digital textile printing, machines and fabrics often get the spotlight. However, the real magic lies in the ink. It is the ink that carries color, defines sharpness, and ensures durability after washes. Even the most advanced printer cannot deliver high-quality results without the right ink. Therefore, selecting the correct ink becomes essential for top performance. For exporters and fashion brands, choosing the right ink partner is critical to achieving consistent, vibrant, and lasting prints.

What Makes Ink Reliable?

High-quality inks are defined by a few essentials:

- Color Vibrancy – Bright, true-to-design colors that pop on every fabric.

- Sharp Detail – Ability to reproduce fine patterns, gradients, and textures.

- Durability & Fastness – Prints that withstand washing, rubbing, and exposure.

- Compatibility – Seamless performance with fabrics, machines, and papers.

- Cost Efficiency – Optimized ink usage with minimal wastage.

Without these qualities, even top-of-the-line machines may fall short of global export standards. Consequently, manufacturers risk inconsistent print quality.

Why TRUE COLORS Inks Stand Out

At TRUE COLORS, inks are engineered to go beyond ordinary printing needs. Because of in-house R&D and strict quality control, manufacturers, exporters, and fashion brands worldwide place their trust in them.

Here’s why TRUE COLORS inks make the difference:

- Vibrant & Long-Lasting Prints – Bold, consistent colors that stay true even after multiple washes.

- Perfect Compatibility – Designed to work seamlessly with TRUE COLORS machines, fabrics, and sublimation papers.

- High Productivity – Stable ink flow and fast-drying formulas minimize downtime and enable faster production runs.

- Reduced Wastage – Efficient ink release lowers costs per meter while maintaining top quality.

- Sustainable Options – Eco-conscious formulations help manufacturers meet international compliance standards.

With TRUE COLORS inks, print quality is not just enhanced — it is redefined.

Best Practices for Using TRUE COLORS Inks Effectively

To get the best results from digital printing inks:

- Always match inks with the recommended machines and fabrics.

- Store inks in a controlled environment to maintain stability.

- Perform routine printhead maintenance to ensure smooth ink flow.

- Use inks from an integrated supplier like TRUE COLORS to avoid compatibility issues.

By following these practices, businesses ensure that ink performance translates into consistent, high-quality output.

Conclusion

In textile printing, machines may drive the process, but inks define the final impression. With TRUE COLORS ink solutions, manufacturers and exporters achieve unmatched vibrancy, consistency, and durability in every print. When paired with fabrics, machines, and sublimation papers, they create an ecosystem that guarantees reliability from design to delivery.

For businesses aiming to elevate print quality, TRUE COLORS inks are the solution that goes beyond machines.