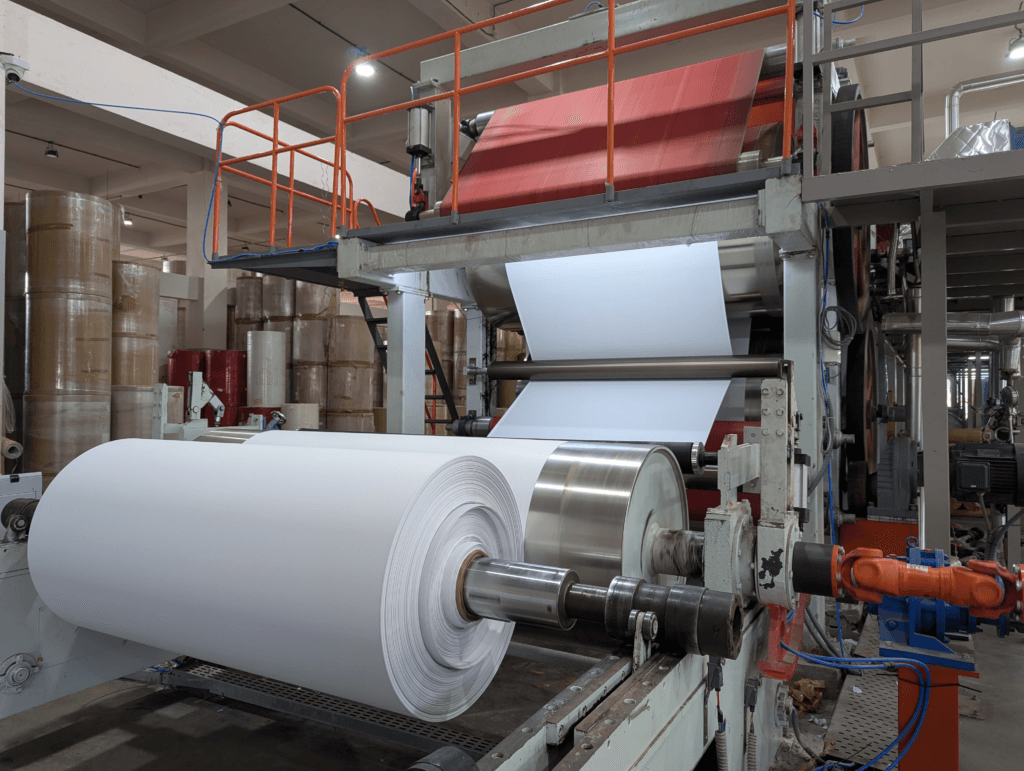

The Hidden Hero of Digital Fabric Printing

When we talk about digital fabric printing, most attention goes to the machines and inks. But the truth is, sublimation paper quality plays an equally critical role in defining the final result. Acting as the carrier of ink before it transfers onto fabric, high-quality sublimation paper directly influences how vibrant, sharp, and consistent your designs appear. Poor-quality paper can mean wasted ink, blurred edges, or dull colors — no matter how advanced your printer is.

How Sublimation Paper Impacts the Final Print

The quality of sublimation paper determines:

- Color Vibrancy – A good paper ensures bright, accurate, and consistent shades that match design intent.

- Ink Release Efficiency – High-grade papers release nearly all the ink during transfer, leaving minimal residue behind.

- Edge Sharpness – Prevents bleeding and ghosting, maintaining crisp details in patterns and text.

- Fabric Compatibility – Works seamlessly across blends, textures, and weights without curl or shrinkage.

- Production Efficiency – Reliable papers reduce errors, misprints, and downtime — saving time and costs in bulk runs.

In short, sublimation paper is not just a medium — it’s the foundation of quality in digital fabric printing.

Why TRUE COLORS Papers Stand Out?

At TRUE COLORS, sublimation paper isn’t treated as a commodity — it’s a technology. Their in-house R&D and strict quality checks ensure every roll performs at production standards. Printers trust TRUE COLORS because their papers are engineered for:

- Quick-Dry Coating – Prevents smudging and bleeding during high-speed printing.

- Complete Ink Release – Maximizes color depth and fabric penetration with minimal waste.

- Dimensional Stability – Resists curling, shrinking, or warping under heat and humidity.

- Batch Consistency – Guarantees that every roll delivers the same reliable results.

- Eco-System Compatibility – Designed to work seamlessly with TRUE COLORS machines, inks, and fabrics.

This integration ensures that printers achieve sharp, vibrant, and durable results, whether producing small runs or scaling to industrial volumes.

Conclusion

In digital fabric printing, the final output is only as good as the sublimation paper you use. Investing in high-quality paper like TRUE COLORS ensures that every design is transferred with clarity, vibrancy, and durability. For manufacturers, exporters, and fashion brands, the choice of paper can mean the difference between average results and standout quality — making it the cornerstone of successful digital printing.