Digital vs Traditional Printing: Which One Wins in 2025?

Why Compare Digital and Traditional Printing in 2025? The textile printing landscape is evolving rapidly. As global markets demand faster turnaround, higher quality and sustainable production, manufacturers are re-evaluating their printing processes. This raises an important question: In 2025, does digital textile printing truly outperform traditional methods?Here’s a clear comparison across the factors that matter most. 1. Speed & Flexibility Digital Printing Traditional Printing Winner for 2025: Digital printing — unmatched agility for fast fashion and dynamic demand cycles. 2. Cost Efficiency & Resource Usage Digital Printing Traditional Printing Winner for 2025: Digital printing — cost-effective, lean and sustainable. 3. Quality, Precision & Design Freedom Digital Printing Traditional Printing Winner for 2025: Digital printing — superior precision and creative flexibility. 4. Sustainability & Environmental Impact Digital Printing Traditional Printing Winner for 2025: Digital printing — aligned with global sustainability standards. 5. Scalability & Supply-Chain Control Digital Printing Traditional Printing Winner for 2025: Digital printing — best suited for flexible and modern supply chains. Conclusion In 2025, the verdict is clear:Digital textile printing outperforms traditional methods across speed, cost, quality, sustainability and flexibility. While traditional printing may still hold value for extremely large-volume runs, the future belongs to digital-first manufacturers. At True Colors, this digital future is powered through an integrated ecosystem of advanced digital printers, inks, papers and job-work services — offering manufacturers a faster, cleaner and more profitable way to print. For textile businesses looking to stay competitive in 2025 and beyond, the message is simple:Choose digital. Choose agility. Choose the future.

5 Reasons Every Textile Manufacturer Should Shift to Digital Printing

Why Move to Digital Textile Printing? The textile industry is in transition — traditional printing methods are giving way to more responsive, efficient and sustainable processes. For manufacturers seeking to stay competitive, embracing digital textile printing is no longer optional.Here are five powerful reasons why the shift is essential. 1. Agility & Shorter Lead Times Digital printing removes the need for long setups, screens and plates — enabling faster changeovers and quicker sampling. In a world where fashion cycles are shrinking, agility becomes a competitive advantage. 2. Cost Efficiency & Waste Reduction Digital textile printing significantly reduces resource consumption compared to conventional methods. With increasing cost pressures on textile mills, digital printing helps maintain healthier margins. 3. Better Supply-Chain Control Digital workflows simplify production and reduce dependency on multiple vendors or lengthy processes. This streamlined production chain supports consistency and reduces disruption in volatile markets. 4. Quality, Versatility & Innovation Digital textile printing enables manufacturers to explore new design possibilities without limitations. From fashion apparel to home décor and customised products, digital printing opens doors for greater creativity. 5. Sustainability & Market Differentiation Sustainability is becoming a decisive factor in global textile sourcing. For exporters, this becomes a value-adding differentiator. Conclusion For textile manufacturers planning the next decade, the shift to digital textile printing is more than a technological upgrade — it’s a strategic evolution. It delivers agility, cost savings, quality, sustainability and sharper supply-chain control. At True Colors, these principles come together in an integrated ecosystem of advanced machines, inks, papers and job-work services — offering a future-ready path for manufacturers aiming to stay ahead. If you’re still relying on conventional methods, the message is clear:Move to digital printing now — before the opportunity to lead the market passes.

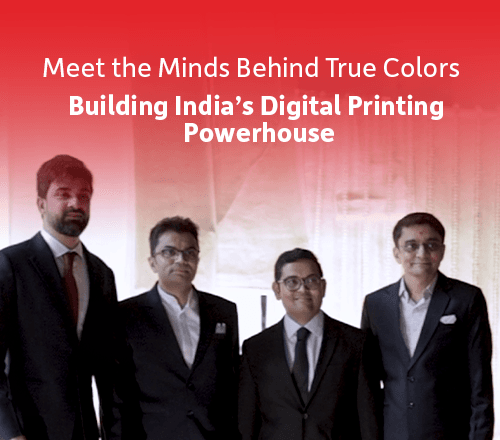

Meet the Minds Behind True Colors — Building India’s Digital Printing Powerhouse

In the heart of Surat, a group of four innovators set out to redefine India’s textile future. Their shared vision led to the creation of True Colors Limited — a brand that has become one of India’s largest and fastest-growing ecosystems in digital textile printing. From installing India’s first sublimation printer, to building a vertically integrated platform offering machines, inks, papers, and job-work printing — the True Colors leadership team has turned ambition into a national success story. Their approach blends innovation with purpose, and passion with scale. Mr. Satish Panchani — The Visionary Strategist Role: Executive Director & CEO Satish Panchani is the strategic backbone of the company. With a blend of technical know-how and leadership insight, he crafted the idea of a single ecosystem where textile manufacturers get everything under one roof — machinery, consumables, and professional service. Because of his vision, True Colors now houses 650+ employees, 2 lakh sq. ft. of infrastructure, and 1,200+ machine installations across India. Satish drives a culture where technology, teamwork, and transformation move together. Mr. Sanjay Desai — The Tech & Sourcing Powerhouse Role: Managing Director With strong global sourcing expertise, Sanjay Desai ensures True Colors always stays ahead in technology. He leads international partnerships, including major industry names such as Hopetech, Konica Minolta, and Pengda. Moreover, Sanjay simplifies the shift from traditional to digital printing for countless manufacturers. His ability to align innovation with practical industry needs helps businesses upgrade with confidence. Mr. Ashish Mulani — The Fabric & Operations Specialist Role: Chairperson & Executive Director Ashish Mulani brings over 12 years of fabric processing experience to True Colors. With deep insights in textile behavior, print quality, and finishing processes, he strengthens day-to-day execution. He manages the printed fabrics and job-work division, enabling customers to access finished fabric output. As a result, True Colors becomes not just a machinery partner — but a complete printing solution provider. Mr. Sagar B. Mulani — The Technical Mind & Workflow Architect Role: Executive Director & CFO Sagar Mulani leads the sublimation paper vertical while ensuring world-class color profiles and digital workflows. His expertise guarantees that every print meets global expectations. Additionally, he ensures strong financial systems and process discipline, which keeps the company scalable, efficient, and resilient. A Leadership Team That Built an Ecosystem The True Colors leadership team shares one core belief:India can lead the global textile industry if empowered with advanced digital tools and sustainable practices. Through their collective strengths: Thousands of manufacturers have shifted from screen to digital printingIndia’s largest after-sales network for textile printers was establishedSolar energy powers more than 20% of operationsEfficiency increased while resource wastage reduced Consequently, True Colors is trusted by exporters, fashion brands, and industrial fabric manufacturers across India. A Culture of Innovation, Trust & Collaboration Each founder represents a unique core: Together, they form a leadership model where collaboration drives capability — and customer success shapes every decision. Their passion continues to evolve digital textile technology in India. Conclusion The story of True Colors goes beyond business milestones. It is proof that Indian innovation, when supported by strong leadership, can transform entire industries. Guided by the True Colors leadership team, India’s digital textile printing landscape is advancing rapidly — from Surat to global markets. They aren’t just printing fabrics…they are printing a new future for Indian manufacturing — one breakthrough at a time.

How True Colors IPO Reflects the Future of Indian Textile Manufacturing

The True Colors IPO is not just another listing on the Indian stock market. It reflects a larger transformation happening within India’s textile sector — a shift driven by digital adoption, modernization of traditional workflows, and the rise of integrated supply chains. As demand grows for faster, cleaner, and more flexible printing methods, digital textile printing is emerging as a key engine of growth. Therefore, this IPO signals where the industry must head next. A Strategic IPO Fueling Digital Innovation True Colors raised ₹127.96 crore through its IPO, with a price band of ₹181–191 per share and a lot size of 600 shares.It included: Because a large portion is a fresh issue, funds will directly support expansion and technology upgrades. Moreover, strong subscription levels clearly indicate investor confidence in digital-led textile businesses. The IPO proceeds are primarily allocated for: This strategic utilization supports both business growth and broader industry upliftment. Why the True Colors IPO Matters for the Textile Landscape Transition Toward Integrated Manufacturing Models Historically, Indian textile units sourced machines, inks, and printing services from separate vendors.However, customers now seek: True Colors already operates across all three critical segments: Therefore, the company’s integrated business model directly aligns with future industry needs. Expanding Domestic Strength With Global Ambition With operations rooted in major textile centers like Surat, Panipat, and Tirupur, True Colors plays an instrumental role in powering regional manufacturing. Additionally, India’s export competitiveness depends heavily on high-speed and low-waste printing. Digital textile printing enables both. Thus, the IPO strengthens India’s vision of becoming a global textile powerhouse, not just a low-cost production hub. Industry-Wide Implications of the True Colors IPO The market is clearly signaling strategic priorities: Consequently, the True Colors IPO sparks momentum for a more advanced, future-ready manufacturing sector. Conclusion The True Colors IPO represents more than financial growth — it symbolizes a new direction for Indian textile manufacturing. The future demands digital-first operations, integrated systems, faster turnaround, and sustainable processes. True Colors is already delivering on this blueprint. As the textile industry continues to evolve globally, companies that embrace advanced printing ecosystems today will define tomorrow’s market leaders.True Colors isn’t just part of this future — it is helping build it.

Digital Textile Printing in India: Opportunity, Growth & Role of Hopetech

Digital textile printing in India is transforming the country’s textile sector at a rapid pace. Today, manufacturers can deliver superior quality, faster production, and eco-friendly results. Moreover, with rising consumer demand for personalization and sustainability, this technology has become a powerful growth driver for the entire industry. Why Digital Textile Printing Matters Digital printing has introduced a smarter way to print textiles. Unlike traditional methods, it offers multiple advantages that directly impact business growth. Key Benefits These features clearly show why digital textile printing in India is becoming the preferred choice for forward-thinking manufacturers. Why Manufacturers Rely on TRUE COLORS TRUE COLORS continues to lead this revolution by offering world-class technology and reliable support. Through its partnership with Hopetech, the company ensures Indian manufacturers have access to efficient, high-performance printing machines. Hopetech Solutions Offered by TRUE COLORS Additionally, TRUE COLORS provides strong after-sales service, operator guidance, and long-term maintenance support. As a result, clients enjoy maximum uptime and higher returns on their investment. Best Practices for Success To fully benefit from digital printing technology, manufacturers should: Because of these practices, printing units can achieve consistency, efficiency, and cost savings. Conclusion Digital textile printing in India is opening new doors for innovation and business growth. With TRUE COLORS and Hopetech working together, Indian textile manufacturers can embrace modern printing solutions and scale confidently. As the industry continues to evolve, those who adopt advanced technology today will be the leaders of tomorrow.

High-Precision Printing with Konica Minolta Nozzle Technology

In the realm of digital textile printing, precision is paramount. Konica Minolta nozzle technology digital textile printing stands at the forefront of this precision, enabling manufacturers to achieve exceptional print quality and efficiency. Paired with TRUE COLORS’ commitment to innovation, this technology is transforming the landscape of textile printing in India. Konica Minolta’s Nozzle Technology: A Leap Forward Konica Minolta’s Nassenger series of textile printers are equipped with high-density, multi-nozzle inkjet heads developed in-house. These printheads are designed to deliver sharpness and high-density quality, ensuring vibrant and detailed prints on various fabrics. The integration of small-droplet technology allows for precise ink deposition, resulting in fine details and smooth gradations in printed designs. Key Features and Benefits TRUE COLORS: Bringing Global Technology to India TRUE COLORS, a leading provider of digital textile printing solutions in India, has partnered with Konica Minolta to bring this cutting-edge technology to local manufacturers. By offering the Nassenger series printers, TRUE COLORS enables Indian textile businesses to produce high-quality prints that meet international standards. Conclusion Konica Minolta nozzle technology digital textile printing represents a significant advancement in digital textile printing, offering unparalleled precision and efficiency. Through its partnership with TRUE COLORS, this technology is now accessible to Indian manufacturers, empowering them to produce superior-quality textiles that can compete in the global market.

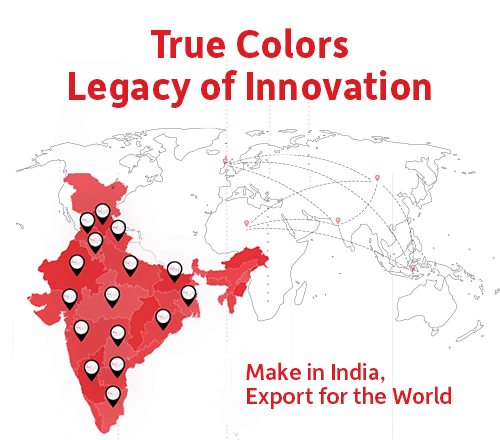

True Colors Legacy of Innovation: Make in India, Export for the World

In the heart of Surat, Gujarat—a city known for its rich textile heritage—TRUE COLORS has become a symbol of innovation and progress. Founded in 2013 by four visionary entrepreneurs, the company set out to reshape India’s textile landscape. Today, their work reflects a powerful blend of quality, sustainability, and advanced technology. Because of this commitment, TRUE COLORS digital textile printing India now stands strong on both local and global platforms. Pioneering Digital Textile Printing in India TRUE COLORS started with a bold idea: introducing India’s first sublimation textile printer. This step marked a clear shift from traditional printing methods. The new approach brought sharper details, brighter colors, and significantly lower environmental impact. Despite early challenges—such as equipment failures and natural calamities—the company stayed focused. With resilience and vision, they continued modernizing the industry. Today, TRUE COLORS provides a wide range of solutions, including: These offerings help Indian manufacturers adopt modern and efficient printing systems. Make in India: Strengthening Local Manufacturing TRUE COLORS strongly supports the Make in India initiative. The company designs and manufactures advanced digital textile printing machines within India. As a result, local manufacturers get technology that is not only affordable but also tailored to their unique requirements. Their state-of-the-art facilities and a skilled team of more than 70 experts further reinforce this mission. With these resources, TRUE COLORS ensures that every machine aligns with the needs of Indian textile units. Exporting Excellence: Competing on a Global Stage While the company is firmly rooted in India, it also looks outward. TRUE COLORS has successfully reached global markets, including the Middle East, Southeast Asia, and parts of Europe. This international growth is driven by: By focusing on performance and reliability, TRUE COLORS has built trust beyond India’s borders. Sustainability at the Core Sustainability plays a central role in TRUE COLORS’ operations. Their digital textile printing machines are designed to reduce water usage, lower energy consumption, and minimize waste. Additionally, eco-friendly inks and materials help ensure cleaner and safer production practices. Because global markets increasingly demand sustainable solutions, TRUE COLORS is perfectly aligned with international expectations. Conclusion TRUE COLORS’ journey—from a local startup to a global force—shows the power of innovation and resilience. Through the Make in India approach, paired with world-class manufacturing standards, the company has redefined the textile printing industry. As textile manufacturing continues to evolve, TRUE COLORS digital textile printing India will keep leading the transformation. With innovation, sustainability, and global vision at its core, TRUE COLORS is not only printing fabrics—it is shaping the future of India’s textile industry.

How True Colors Bridges Local Manufacturing with Global Standards

In the fast-changing world of textile manufacturing, staying ahead requires consistent innovation and reliable quality. TRUE COLORS, a Surat-based leader in digital textile printing, has mastered this balance. By blending advanced technology with a deep understanding of local production needs, the company has become a trusted name in TRUE COLORS digital textile printing in India. As a result, they now serve as a bridge between India’s textile heritage and global manufacturing expectations. A Legacy of Innovation TRUE COLORS began its journey in 2013 with a clear vision—to transform India’s textile printing landscape. They introduced India’s first sublimation textile printer, which marked a major shift toward digital printing. Since then, they have consistently expanded their capabilities. Today, their offerings include: Because of these innovations, TRUE COLORS has established itself as a one-stop solution for modern textile manufacturers. Strategic Partnerships for Global Excellence To maintain international quality standards, TRUE COLORS has partnered with leading global brands. These collaborations allow Indian manufacturers to access world-class technology with local support. Konica Minolta Konica Minolta is known for its high-speed and high-precision printing technology. Their machines help Indian manufacturers produce export-ready textiles with consistent accuracy and reliability. Hopetech Hopetech focuses on eco-friendly and energy-efficient digital printing systems. Their Q1 model, for instance, reduces environmental impact while ensuring fast printing speeds and precise inkjet output. Through these partnerships, TRUE COLORS delivers digital printing technology in India that matches global benchmarks. A Complete Ecosystem for Manufacturers TRUE COLORS offers far more than just machines. They provide an integrated ecosystem that helps textile manufacturers operate smoothly and efficiently. End-to-End Solutions Manufacturers can source everything they need from one place—printers, inks, and sublimation papers. This ensures compatibility, better performance, and consistent output. Training and Technical Support To help clients use their machines effectively, TRUE COLORS conducts training programs and provides ongoing after-sales service. Consequently, manufacturers can fully utilize the advanced features of their equipment. Focus on Sustainability The company promotes energy-efficient processes and eco-friendly printing practices. This aligns Indian production with global sustainability goals. Empowering Local Manufacturers for Global Markets By offering international technology with local expertise, TRUE COLORS strengthens India’s position in the global textile market. Their integrated solutions enable manufacturers to improve quality, increase efficiency, and adopt sustainable practices. Hence, TRUE COLORS digital textile printing in India is not only modern but globally competitive. Conclusion TRUE COLORS proves that when local innovation meets global standards, industry transformation becomes inevitable. Through strategic international partnerships, a complete manufacturing ecosystem, and a strong commitment to quality and sustainability, they are empowering Indian textile manufacturers to excel worldwide. Their approach not only meets global expectations—it sets new standards for the future of digital textile printing in India.

True Colors Brings Konica Minolta Printing Machines to India

The demand for advanced printing technology is rapidly increasing, and TRUE COLORS is leading the transformation with its latest initiative. By partnering with Konica Minolta, TRUE COLORS is bringing world-class digital textile printing machines to India, helping manufacturers achieve export-quality results with greater efficiency. This collaboration marks an important milestone for the textile sector, especially for businesses seeking high-performance and sustainable printing solutions. Konica Minolta: A Global Leader in Digital Textile Printing Konica Minolta has earned decades of trust for its innovation in printing technology. Its digital textile printing machines are known for their precision, speed, and sustainability. Moreover, the brand’s Nassenger series is widely used by textile manufacturers around the world who want consistent quality with minimal environmental impact. This makes Konica Minolta digital textile printing in India a major step forward for domestic manufacturers. TRUE COLORS: Accelerating India’s Shift to Digital Printing TRUE COLORS has always focused on modernizing the Indian textile printing ecosystem. With operations across Surat, Delhi, and Mumbai, the company has continuously helped manufacturers switch from traditional processes to advanced, digital-first solutions. By bringing Konica Minolta’s digital textile printing technology to India, TRUE COLORS aims to empower businesses with: As a result, Indian manufacturers are now better equipped to compete in international markets. Nassenger Series: Where Performance Meets Perfection Konica Minolta’s Nassenger printers are engineered for reliable, high-volume production. Additionally, they offer unmatched print sharpness and color consistency. Nassenger 8 Nassenger 10e These machines also include intelligent features such as flexible ink adjustments, advanced head maintenance, and high-density inks, making them a perfect choice for Indian textile units looking to upgrade. TRUE COLORS: Your Partner in Digital Transformation TRUE COLORS doesn’t just provide machines—it provides complete support. The company’s team of more than 70 trained experts assists with: With this strong network, the introduction of Konica Minolta digital textile printing in India becomes more than a technology upgrade—it becomes a long-term growth opportunity for the textile industry. Conclusion The partnership between TRUE COLORS and Konica Minolta marks a major milestone in India’s textile journey. By introducing Konica Minolta digital textile printing machines in India, TRUE COLORS is helping manufacturers produce export-quality fabrics with confidence, efficiency, and sustainability. This collaboration will undoubtedly pave the way for stronger global competitiveness and a brighter future for Indian textiles.

Why Machine Maintenance & After-Sales Support Matter — True Colors Advantage

The Role of Machine Maintenance in Digital Textile Printing In high-speed digital textile printing, the machine is the backbone of production. Regular maintenance ensures consistent print quality, reduces downtime, and prolongs the life of your equipment. A well-maintained printer delivers vibrant colors, accurate designs, and smooth operations across all fabric types. Without proper maintenance, even advanced printers like the Hopetech, Konica Minolta can face issues such as misalignment, ink inconsistencies, and wear on moving components, which ultimately affects output quality and efficiency. What Makes After-Sales Support Crucial? These factors keep production lines running smoothly, protect investments, and uphold the high standards expected in textile printing. Why Printers Trust TRUE COLORS TRUE COLORS is a trusted partner for printers because their approach combines technology, support, and expertise: Best Practices for Maintenance & Support To ensure longevity and efficiency of your machines: Adhering to these practices guarantees that your digital printing setup remains reliable, efficient, and productive. Conclusion Machine maintenance and after-sales support are not optional — they are vital for consistent quality and business success. TRUE COLORS combination of cutting-edge printers, expert support, and a robust service network ensures that manufacturers can focus on creativity and output, while their machines perform flawlessly. With TRUE COLORS, printers gain reliability, peace of mind, and a competitive edge in the digital textile industry.